|

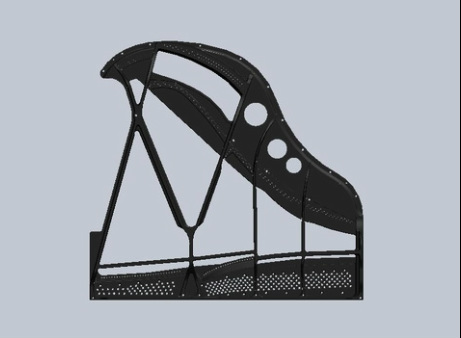

From Computer Design to the physical world, this is George F. Emerson's CAD rendering of the Cunningham Plate based on the original Philadelphia Scale Design and Mr. Emerson's ideas involving plate mass and bridge tensions.

|

Like waiting for an expected child, the Cunningham team travels to the foundry to inspect and approve the bass-wood rendering of the new plate design. The molds can be seen in the background. Enjoy the production pics to follow!

|

|

This set of keys is waiting for preparation and installation into a piano. Each key set is weighed off individually for the piano into which it is installed.

|

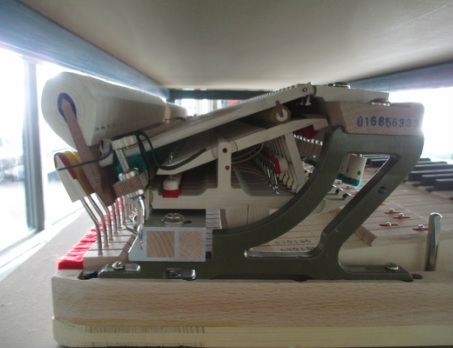

The action is now complete and awaiting regulation and installation into a piano.

|

|

Installing an action into a piano requires adjustment, voicing, and re-adjustment for the parts to work as required. Every Matchless Cunningham receives finishing at our Philadelphia facility before it is delivered.

|

Tim Oliver (left), Co-Owner of Cunningham Piano Company, spends time with Paul Rea at the manufacturing facility in Ning Bo. Paul is there many months each year and helps us in quality control when Tim is unable to be there.

|